Welcome

to the future of dental restorations. In keeping with

our tradition of bringing you the latest in cutting

edge developments and the newest technologies, LHM is

proud to offer our clients CAD CAM engineered and milled

ZIRKONIA restorations. Prepared from factory sintered

Zirconium Dioxide, Zirkonia is as incredibly strong as

it is exceptionally aesthetic. With a flexural strength

of over 1300 MPa, Zirkonia is over 30% stronger than any

other product on the market today. Welcome

to the future of dental restorations. In keeping with

our tradition of bringing you the latest in cutting

edge developments and the newest technologies, LHM is

proud to offer our clients CAD CAM engineered and milled

ZIRKONIA restorations. Prepared from factory sintered

Zirconium Dioxide, Zirkonia is as incredibly strong as

it is exceptionally aesthetic. With a flexural strength

of over 1300 MPa, Zirkonia is over 30% stronger than any

other product on the market today.

- Milled, metal free crowns and long span bridges

up to 6 units

- Translucent Zirkonia core, biocompatible and strong

- Preparations no more demanding than older all ceramic

systems

- Can be cemented using traditional, tried and tested

techniques

Call us today to experience the METAL FREE REVOLUTION

Light

weight, biocompatibility, no complaints of a harsh metallic

taste ...titanium has many advantages as a material

in restorative dentistry. But because it is highly technique-sensitive

and requires special equipment, many laboratories shy

away from recommending titanium to their clients. Light

weight, biocompatibility, no complaints of a harsh metallic

taste ...titanium has many advantages as a material

in restorative dentistry. But because it is highly technique-sensitive

and requires special equipment, many laboratories shy

away from recommending titanium to their clients.

At LHM, we are accustomed to handling demanding materials

and situations every day. We consider titanium as an option

for a wide variety of applications, including implants,

conventional crown and bridge work and denture palates

and frameworks and most importantly for patients with

allergies.

We

are one of the few Canadian Laboratories able to offer

our clients the benefits of on-site laser welding. This

technology is necessary for modifying or repairing titanium

substructures. It can also simplify and expedite many

procedures involving more conventional alloys. We

are one of the few Canadian Laboratories able to offer

our clients the benefits of on-site laser welding. This

technology is necessary for modifying or repairing titanium

substructures. It can also simplify and expedite many

procedures involving more conventional alloys.

Computers have changed every aspect of our lives today,

and the work we produce at LHM is no exception.

We

harness these powerful new technologies to enhance our

communication with you: We

harness these powerful new technologies to enhance our

communication with you:

If questions about shade, design or contour arise during

the fabrication of a restoration, we can transmit and

receive digital photographs of patients, wax-ups or

frames to allow you to intervene at an early stage of

the process and save time.

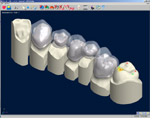

For

the construction of fixed metal-free or PFM restorations,

LHM has integrated computer designing technology and

fabricating software along with a state of the art wax

printer to create wax patterns and milled restorations.

We can program this system to remember your preferences

in contacts, occlusion and emergence and with the push

of a button create a perfectly supported framework for

your restoration. For

the construction of fixed metal-free or PFM restorations,

LHM has integrated computer designing technology and

fabricating software along with a state of the art wax

printer to create wax patterns and milled restorations.

We can program this system to remember your preferences

in contacts, occlusion and emergence and with the push

of a button create a perfectly supported framework for

your restoration.

LHM is old-fashioned, though, in treating computers

as tools. We refine their product with the years of

experience that have made our quality an industry standard.

|